Our automated liquid handling instruments reduce the time spent on repetitive pipetting tasks at any throughput level.

Automated liquid filling systems.

Filamatic is a proven leader within the liquid packaging industry.

Our liquid filling machines are used worldwide to fill a range of sensitive containers like syringes vials micro vials tubes micro tubes as well as perform a series of closing functions stoppering plugging crimping and overcapping.

Data scale is able to provide application system integration providing innovative real world solutions for your liquid filling and automation needs.

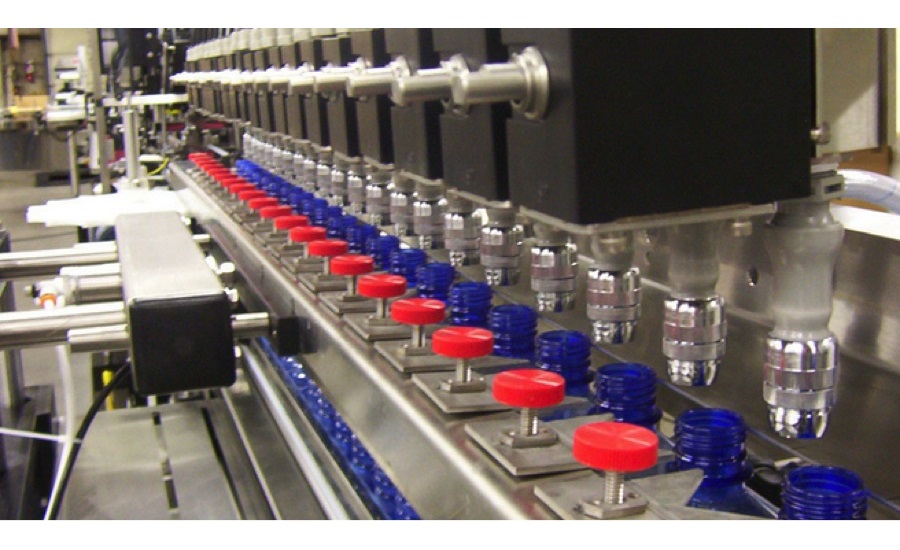

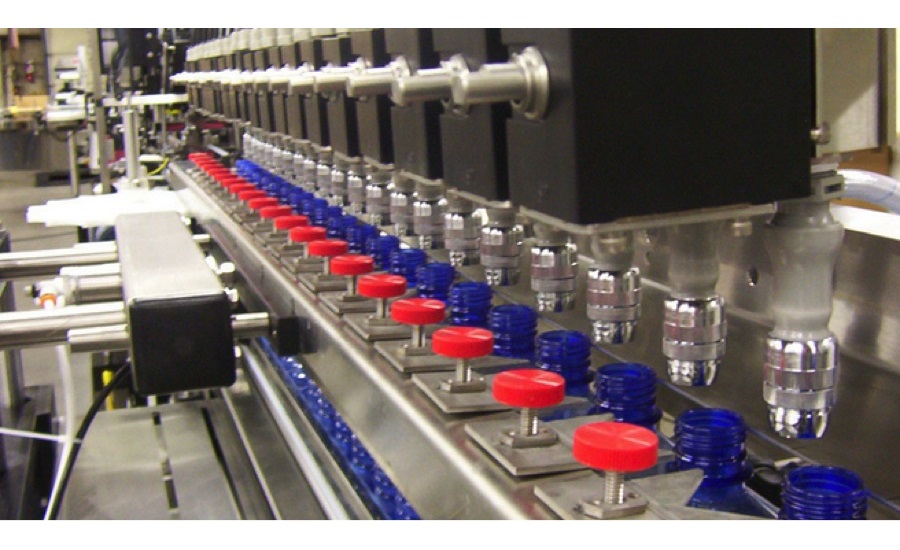

Automatic filling machines will normally use a belt conveyor system to index containers into and out of the filling area.

Inline filling systems designs and manufactures a world class application specific liquid filling machine for almost all major industries.

Our challenge is to take the customer expectations and adapt our products to fulfill them so most of our projects are completely tailor made.

Quality and controlled filling.

Liquid filling systems can be manufactured as automatic filling machines semi automatic tabletop filling machines and even unique uniframe filling systems.

Manufactured here in north america we are very proud of our range of in line liquid fillers from our simple one head little filler as shwn here to fully automatic multi head machines.

Our liquid filling machines range from simple single head manually operated filling machines through to fully automated multi head filling systems using either vacuum level filling or volumetric piston filling technologies.

With over 700 packaging machinery products engineering experience spanning 20 years and 100mm of installations installed in over 50 countries inline filling systems is your worry free choice for turnkey liquid packaging installations.

They are suitable for almost any liquid including viscous liquids containing particles such as foods and can cater for containers in the 5ml to 10 litre fill range.

We offer systems ideal for medium or high throughput applications meeting multiple liquid handling requirements that include channels microplate type or liquid volumes.